In 1913, Henry Ford installed the first moving assembly line for the mass production of an entire automobile. His innovation reduced the time it took to build a car from more than 12 hours to two hours and 30 minutes.

Lean manufacturing is a management philosophy derived from the Toyota Production System (TPS) and is a systematic method for eliminating waste within a manufacturing system. Lean addresses waste created by overburden and uneven workloads. By removing everything that does not contribute value, lean manufacturing makes obvious what adds value, by reducing everything else which does not.

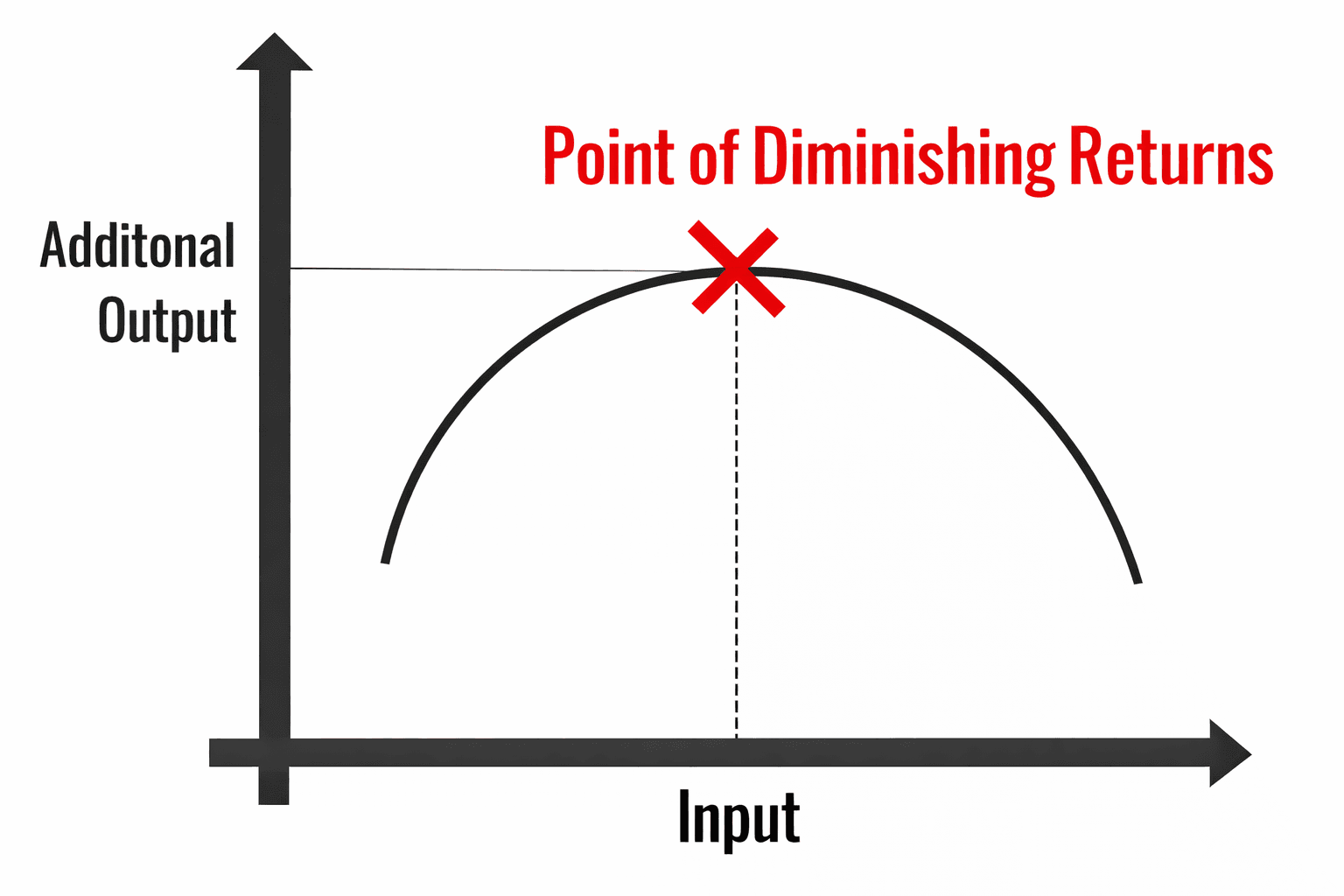

The Law of Diminishing Returns is an economic principle stating that as an investment in a particular area increases, the rate of profit from that investment, after a certain point, cannot continue to increase if other variables stay at a constant. As the investment continues past that point, the return diminishes progressively.

How, and why, should these principles matter to your business? First, at its core, your high-volume photography business is an assembly line. So, let's look at one aspect of your assembly line to apply these principles. The size of your image files.

Of course, everyone knows that larger image files produce higher quality prints. However, if the largest print size you'll be delivering is an 8x10, why output files at any higher resolution than needed to produce the quality that meets the standards you've established? Are you just shooting RAW and exporting high-quality JPEGS without much thought about the impact that size will have on your productivity? Just how much thought do you give to the size of your files as they travel through your workflow?

Why should you care about this?

Ask yourself, how well would Ford's assembly line have functioned if any aspect of it was not standardized or was left to chance? We're using file size for this example, but you should routinely scrutinize all aspects of your business using a systematic method for eliminating waste to optimize the output of your factory — your Engine of Growth.

Let’s do some math. We’ll start with a project that contains 4,000 images, each with an average file size of 18 MB, for a total project size of 72 GB (4,000 × 18 MB = 72,000 MB = 72 GB).

Fast connection speeds are often touted by internet providers, but most people don’t realize that upload and download speeds can vary greatly — with upload speeds often being many times slower than download speeds. Running your own speed test will quickly reveal this difference. In our example connection, the download speed measured 34 megabits per second (Mbps), while the upload speed was just 10 Mbps.

That single optimization reduces upload time by roughly two-thirds, saving more than 10 hours per project.

A megabit is one-eighth the size of a megabyte, which means an upload speed of 10 Mbps translates to roughly 1.25 megabytes per second (MB/s). In practical terms, transferring a 1 MB file in one second requires an 8 Mbps connection. (Mb = megabits, MB = megabytes.)

At an upload speed of 10 Mbps, transferring a 72 GB project would take a little over 16 hours under ideal conditions — and that’s just the upload. Larger files also take longer to index, sort, and transfer across your connected platforms, not to mention every other time those files are moved before and after Snapizzi in your workflow.

For the sake of this example, we’ll focus on upload time alone. If testing shows that the smallest image size required to produce a quality print at your largest offering is 6 MB, the same project drops to 24 GB total. At 10 Mbps, that upload now takes just over 5 hours.

That single optimization reduces upload time by roughly two-thirds, saving more than 10 hours per project — before accounting for any of the downstream efficiency gains.

Process management is critical to effective project management. If a photography business like the one in this example is generating 100,000 images per year, this small change alone saves nearly 12 full days of upload time annually.

Still think file size doesn't matter much?

Are you actively identifying waste and inefficiencies in your business to reclaim your time and increase profitability?

If not — it begs the question: why not?